LOCTITE 638: The Ultimate High-Strength Retaining Compound for Maximum Bonding Power

Loctite 638 – High-Strength Retaining Compound

Choose Loctite 638 Green Retaining Compound (50ml) — trusted worldwide for 4,000+ psi strength, oil resistance, and high-temp durability. Buy now for stronger, longer-lasting metal bonds.

🛠️ Ready to Strengthen Your Machinery?

If you work with motors, gears, shafts, bearings, or any machinery that demands a reliable, high-strength metal bond, then LOCTITE® 638™ Retaining Compound is your best solution.

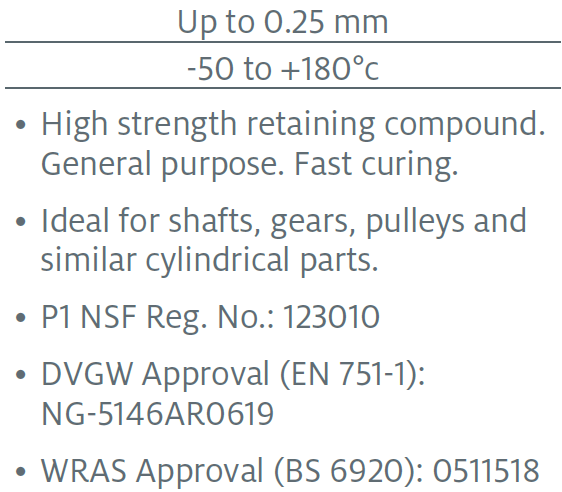

Engineered with anaerobic acrylic technology, this green liquid adhesive is specifically designed for bonding cylindrical fitting parts where gaps can reach up to 0.25 mm, and where maximum strength at room temperature is essential.

Let’s explore what makes Loctite 638 one of the most powerful and trusted retaining compounds worldwide—and why it’s the go-to adhesive for professionals across automotive, industrial, and mechanical applications.

🔹 What Is LOCTITE 638 Used For?

LOCTITE 638 is used for retaining and bonding metal cylindrical components such as:

- Bushings and sleeves into housings

- Shafts and gears

- Bearings and rotors

- Pulley and sprocket assemblies

It cures in the absence of air (anaerobic cure) between close-fitting metal surfaces, forming a solid thermoset plastic that locks assemblies in place, prevents loosening, and stops leakage caused by shock and vibration.

This high-strength compound has become an industry standard in maintenance, repair, and manufacturing sectors where mechanical reliability is non-negotiable.

🔹 Product Overview: LOCTITE 638 Retaining Compound

| Property | Details |

|---|---|

| Technology | Acrylic (Anaerobic) |

| Chemical Type | Urethane methacrylate |

| Color (Uncured) | Green |

| Viscosity | High |

| Cure Method | Anaerobic / with Activator |

| Application | Retaining cylindrical parts |

| Strength | High |

| Appearance under UV Light | Fluorescent |

| Temperature Range | -55 °C to +180 °C (up to 200 °C peak) |

| Gap Fill | Up to 0.25 mm |

| Packaging | LOCTITE 638 – 50 ml, 250 ml |

🔹 What Color Is LOCTITE 638?

LOCTITE 638 is green, which makes it easy to identify during application.

It’s often referred to as Loctite Green 638, distinguishing it from other grades such as Loctite 243 (blue) or Loctite 271 (red). The green color also fluoresces under UV light, helping quality inspectors confirm coverage during assembly.

🔹 What Is LOCTITE 638 Adhesive 50ml High Strength?

The 50 ml bottle is the most popular retail and workshop size of LOCTITE 638.

It’s compact yet long-lasting—one bottle can bond hundreds of components, depending on the surface area.

The 50 ml size is ideal for:

- Maintenance engineers

- Automotive workshops

- Industrial assembly lines

- DIY mechanics working on restoration projects

When applied correctly, the Loctite 638 50 ml gives unmatched performance: extremely high shear strength, long-term reliability, and exceptional tolerance to oils and contaminants.

🔹 How LOCTITE 638 Works

Once applied to the metal surface and assembled, air is excluded between the parts.

The adhesive then polymerizes (cures), forming a solid thermoset plastic that bonds the surfaces together.

This creates a 100% contact seal, eliminating micro-movement that leads to wear, fretting, and loosening over time.

The curing process is chemical, not mechanical—so there’s no shrinking, warping, or added stress on parts.

🔹 LOCTITE 638 Curing Time

The curing speed of Loctite 638 depends on several factors:

| Condition | Time to Handling Strength | Full Cure |

|---|---|---|

| Steel | 10–20 min | 24 h |

| Stainless Steel (passive) | 1–3 h | 24 h |

| Aluminum | 30–40 min | 24 h |

| With Activator (SF 7649™ or SF 7471™) | 5–10 min | 1–2 h |

If you need faster cure time, apply LOCTITE Activator 7649 on one surface before bonding—it dramatically accelerates curing, especially on passive metals like stainless steel.

🔹 LOCTITE 638 Temperature Range

Loctite 638 performs reliably from -55 °C to +180 °C, and even withstands short-term peaks up to 200 °C.

That makes it suitable for high-temperature machinery, automotive engines, and industrial equipment operating under extreme thermal cycles.

Even after years of service, it maintains over 90% of its original strength when exposed to motor oil, fuel, brake fluid, ethanol, or bio-diesel—proven through 5,000-hour laboratory tests.

🔹 Loctite 638 vs 648 — What’s the Difference?

Both Loctite 638 and Loctite 648 are high-strength retaining compounds—but here’s how they compare:

| Feature | Loctite 638 | Loctite 648 |

|---|---|---|

| Gap Fill | Up to 0.25 mm | Up to 0.15 mm |

| Temperature Resistance | Up to 180–200 °C | Up to 175 °C |

| Oil Tolerance | Excellent | Very good |

| Strength | Very High | High |

| Color | Green | Green |

| Viscosity | Higher | Medium |

👉 If you work with worn parts or slightly larger bond gaps, choose Loctite 638.

If your assembly involves tight tolerances and precision parts, Loctite 648 may be sufficient.

However, for maximum holding power, Loctite 638 is the stronger and more versatile choice.

🔹 Loctite 638 Equivalent Products

Some users look for Loctite 638 equivalents due to availability or cost.

Here are a few comparable products (always verify suitability before substitution):

- Permabond HM 160 – High-strength anaerobic retainer

- 3M Scotch-Weld RT 20 – High-temperature retainer

- Anabond 641 – Green retaining compound for shafts and bearings

However, none match Loctite 638’s balance of high temperature, oil tolerance, and gap-filling performance. Henkel’s formula remains the gold standard in industrial adhesives.

🔹 Loctite 638 MSDS (Material Safety Data Sheet)

Safety is paramount when handling any chemical adhesive.

The LOCTITE 638 MSDS (now SDS) provides vital information on safe handling, storage, and disposal.

Key safety points include:

- Avoid contact with skin and eyes; wear gloves and goggles.

- Use in a well-ventilated area.

- Store between 8 °C and 21 °C in a dry, sealed container.

- Do not return used material to the original bottle to prevent contamination.

Always consult the official Loctite 638 SDS before industrial use. It’s available on Henkel’s website or from your local distributor.

🔹 Outstanding Technical Performance

After 72 hours of curing at room temperature, Loctite 638 achieves exceptional mechanical strength:

| Property | Result |

|---|---|

| Compressive Shear Strength (Steel) | 29 N/mm² (≈ 4200 psi) |

| Compressive Shear Strength (Stainless Steel) | 28 N/mm² |

| Compressive Shear Strength (Aluminum) | 17 N/mm² |

| Breakaway Torque (M10 Bolt/Nut) | 57 N·m |

| Prevailing Torque (M10 Bolt/Nut) | 22 N·m |

This makes it one of the strongest retainers in the Loctite family—perfect for heavy-duty assemblies where failure is not an option.

🔹 Resistance to Oils, Fuels, and Chemicals

Loctite 638 is built to survive real-world conditions.

Tests show it retains 90–100% of its initial bond strength after 5,000 hours of exposure to:

- Motor oil (synthetic 5W40)

- Brake fluid

- Unleaded petrol

- Water/glycol coolant

- Ethanol

- Bio-diesel

- Sodium hydroxide and mild acids

This chemical resistance makes it perfect for automotive, marine, and industrial machinery environments.

🔹 How to Use LOCTITE 638 Retaining Compound

Step 1 – Clean the Surfaces

Use Loctite Cleaner SF 7063 or an equivalent solvent to remove grease, dirt, and oil.

Step 2 – Apply Activator (Optional)

On passive metals or when large gaps exist, use Activator 7649 or 7471 to speed up cure time.

Step 3 – Apply Adhesive

- For slip-fit assemblies: Apply around the leading edge of the male part.

- For press-fit assemblies: Coat both surfaces evenly.

- For shrink-fit assemblies: Apply to the cooled part before heating or inserting.

Step 4 – Assemble Quickly

Rotate during assembly for even coverage. Do not move parts until initial handling strength is achieved.

Step 5 – Full Cure

Allow 24 hours at 23 °C for maximum bond strength.

🔹 Disassembly Instructions

Even though Loctite 638 forms a permanent bond, it can still be disassembled:

- Heat the assembly to approximately 250 °C.

- Disassemble while hot using standard hand tools.

- If needed, clean cured residue with Loctite solvent and a wire brush.

🔹 Storage and Shelf Life

Store unopened bottles between 8 °C and 21 °C in a dry location.

Avoid temperatures below 8 °C or above 28 °C, as these can affect performance.

Never return used material to the original bottle—once exposed to metal and air, it may begin curing.

🔹 Why Choose LOCTITE 638?

✅ High Gap-Filling Ability (0.25 mm)

✅ Superior Oil Tolerance

✅ Works on Active and Passive Metals

✅ High Temperature and Chemical Resistance

✅ Hydrogen Certified (GASTEC QA 214)

✅ Proven Industrial Reliability

When you need a retaining compound that won’t fail, Loctite 638 gives you confidence, consistency, and strength under pressure.

🔹 People Also Ask

Q: What is Loctite 638 used for?

A: It’s used for bonding cylindrical metal parts—like bearings, gears, and shafts—to prevent loosening under vibration and load.

Q: What color is Loctite 638?

A: It’s green and glows under UV light for easy inspection.

Q: What size gap for Loctite 638?

A: It can fill gaps up to 0.25 mm, perfect for slightly worn or loose fits.

Q: What is Loctite 638 adhesive 50 ml high strength?

A: A small-size, high-performance anaerobic adhesive ideal for professional use in maintenance and assembly.

Q: How long does Loctite 638 take to cure?

A: Handling strength is reached in about 10–20 minutes, with full cure in 24 hours at room temperature.

🔹 Where to Buy LOCTITE 638

You can order Loctite 638 (50 ml) or 250 ml bottles from authorized distributors or online platforms like Henkel’s official store, Amazon, or industrial supply partners.

Always ensure the product is genuine—counterfeits may look similar but lack the same performance.

🔹 Final Verdict: The Professional’s Choice

When precision, durability, and safety are paramount, Loctite 638 Retaining Compound stands out as the number-one choice for engineers and mechanics worldwide.

Its high-strength formula, oil tolerance, and temperature endurance make it indispensable for industrial maintenance, automotive repair, and machinery assembly.

With Loctite 638, you’re not just bonding parts—you’re building reliability that lasts for years.