The Ultimate Review of Loctite 2701: Is This the “Green Light” for Your Projects?

If you’ve ever spent hours meticulously assembling a piece of machinery, only to have it rattle itself apart under vibration, you know the frustration. The search for a reliable threadlocker can feel endless, especially when you need something strong, versatile, and trustworthy. You might have heard of the famous Loctite Blue (243) and Red (271), but have you discovered the secret weapon for tough applications? Enter Loctite 2701.

In this deep-dive review, we’re going to unpack everything you need to know about Loctite 2701. We’ll answer your burning questions, explore its unique features, and even walk through a real-world case study to show you why this little green liquid might be the missing piece in your toolbox.

What Exactly is Loctite 2701? A Quick Overview

In simple terms, Loctite 2701 is a high-strength, permanent, green, anaerobic threadlocking adhesive.

Let’s break that down:

- High-Strength & Permanent: This isn’t for parts you plan to take apart regularly. Once it cures, it’s designed to hold fasteners permanently, resisting the toughest shocks and vibrations.

- Green: Its color is a key identifier. While Loctite Blue and Red are common, Green is often used for specific, high-performance applications.

- Anaerobic: This is the magic. It remains a liquid until it’s squeezed between tight-fitting metal threads, where the absence of air triggers it to harden into a tough plastic.

- Low Viscosity: It’s a thin liquid that can easily wick into pre-assembled fasteners—a huge advantage for repairs or fine-tuning.

Who Should Seriously Consider Loctite 2701?

This product isn’t just for everyone; it’s for those who face specific challenges. You should consider Loctite 2701 if you:

- Work in manufacturing, automotive, or heavy machinery maintenance.

- Need a threadlocker that works exceptionally well on inactive metals like stainless steel, plated, or passivated surfaces.

- Require maximum resistance to hot oil and solvents (think engine components, hydraulic systems).

- Want a way to visually inspect for the presence of threadlocker after assembly.

- Have fasteners that are prone to loosening under extreme vibration.

Answering Your Top Questions About Loctite 2701

Before we dive deeper, let’s clear up the most common queries straight from the datasheet.

1. What is Loctite 2701 Used For?

Loctite 2701 is engineered for the permanent locking and sealing of threaded fasteners. Its primary job is to prevent nuts, bolts, and screws from loosening due to shock and vibration. It also creates a tight seal that prevents fluid and gas leakage from threaded connections. Common applications include:

- Engine and transmission components

- Hydraulic fittings and pumps

- Agricultural and construction equipment

- Bolts on machinery frames and assemblies

2. Is Loctite 2701 Permanent?

Yes, Loctite 2701 is classified as a high-strength, permanent threadlocker. The datasheet specifies breakaway torque values of 26-50 N·m on an M10 steel bolt, indicating a very powerful hold. Disassembly typically requires the application of significant heat (around 250°C / 482°F) and tools.

3. How Long Does Loctite 2701 Take to Dry?

This is a critical point. “Dry” and “fully cured” are different. The fixture time (when it starts to hold) and full strength (after 24 hours) vary based on the materials and temperature.

- On Steel: Reaches handling strength in about 10 minutes at room temperature (22°C).

- On Brass: Surprisingly fast, achieving handling strength in just 4 minutes.

- On Stainless Steel: Slower, taking about 25 minutes due to its “inactive” surface.

- Full Cure: It develops its maximum strength over 24 hours.

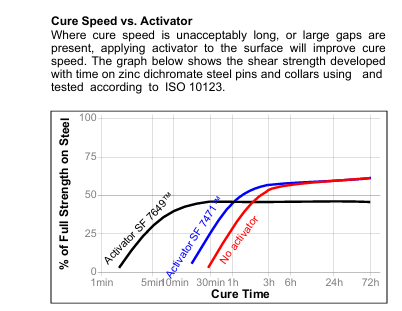

Pro Tip: If you’re working with inactive metals like stainless steel or need a faster set time, using a Loctite primer (like SF 7471 or SF 7649) dramatically speeds up the curing process, as shown in the datasheet graphs.

4. What Color is Loctite 2701?

It is a distinctive green liquid in its uncured state. This isn’t just for looks; it has a crucial quality control feature.

The “Wow” Features: What Makes Loctite 2701 Stand Out?

The UV Fluorescence Superpower

This is, without a doubt, one of its coolest and most practical features. Loctite 2701 fluoresces brightly under UV light. Why does this matter? In an industrial or quality control setting, an inspector can simply shine a black light on an assembly to instantly verify that the threadlocker has been applied correctly and has wicked through the threads. This eliminates guesswork and ensures every product meets the highest safety standards.

Champion of “Inactive” and Coated Metals

Many metals have surface treatments—like zinc dichromate, phosphate coatings, or passivation on stainless steel—that can slow down or prevent anaerobic adhesives from curing properly. Loctite 2701 is specially formulated to tackle this challenge head-on. The datasheet shows it performs robustly on steel, brass, zinc dichromate, and stainless steel, making it incredibly versatile across different manufacturing processes.

Superior Resistance to Heat and Chemicals

Your machinery doesn’t live in a clean, room-temperature bubble. It faces harsh environments. Loctite 2701 is built for them. According to the datasheet, after curing, it retains:

- Excellent hot strength: It can operate continuously at high temperatures.

- Outstanding resistance to motor oil, gasoline, brake fluid, and glycol: After 1000 hours immersed in hot motor oil (125°C), it actually maintained 110% of its initial strength. This is a game-changer for automotive and industrial application

Loctite 2701 vs. The Competition: A Quick Guide

- Loctite 2701 vs. 243 (Blue): Loctite 243 is a medium-strength, removable threadlocker. Use Blue 243 for parts you intend to service with hand tools. Use Green 2701 for permanent assemblies or where higher chemical resistance is needed.

- Loctite 2701 vs. 271 (Red): Both are high-strength and permanent. Loctite 271 is a classic red formula with a higher viscosity (thicker). 2701’s lower viscosity gives it better wicking ability, and its formulation is optimized for coated and inactive metals.

- Loctite 2701 vs. 270 (Red): Loctite 270 is also a high-strength, permanent red threadlocker. The 2701 green formula specifically includes the UV fluorescence feature and is often preferred for its performance on plated surfaces.

A Real-World Case Study: Securing a Hydraulic Press

The Problem:

A local Kenyan metal fabrication shop located in the industrial area was plagued by persistent failures of their main hydraulic press. The large mounting bolts for the central cylinder would consistently loosen after several weeks of operation, causing misalignment, hydraulic fluid leaks, and unplanned downtime. Each stoppage cost thousands of dollars in lost productivity and repair time. They had tried standard threadlockers, but the combination of intense vibration, shock loads, and contamination from hydraulic oil rendered them ineffective.

The Solution:

After analyzing the problem, their maintenance lead identified two key issues:

- The bolts were on passivated stainless steel mounts (an inactive surface).

- The threads were often lightly contaminated with hydraulic oil despite cleaning efforts.

They decided to implement a new protocol using Loctite 2701. The process was simple:

- Bolts and threaded holes were cleaned as thoroughly as possible with a lint-free cloth.

- Loctite 2701 was applied to the bolt threads. Its low viscosity helped it displace minor oil contamination.

- The cylinder was assembled and torqued to specification.

- After assembly, a quick check with a UV light confirmed the threadlocker had wicked correctly through the joint.

The Result:

The result was transformative. The press ran for over eight months without a single instance of bolt loosening. The UV inspection step became a standard part of their quality checklist, providing peace of mind. The shop estimated that this one change saved them over $15,000 in the first year by eliminating downtime and repair costs.

Final Verdict: Should You Buy Loctite 2701?

Loctite 2701 is not a general-purpose, around-the-house threadlocker for IKEA furniture. It is a specialized, industrial-grade adhesive designed to solve specific, tough problems.

Buy Loctite 2701 if:

- You need a permanent, high-strength lock for critical fasteners.

- You work with stainless steel, plated, or other hard-to-bond metals.

- Your assemblies are exposed to vibration, heat, and aggressive fluids like oil or fuel.

- Quality control and traceability are important in your process.

Consider a different product (like Loctite 243) if:

- You need to disassemble the parts later with standard tools.

- You are working on basic steel or aluminum assemblies without harsh chemical exposure.

- Your budget is a primary concern for non-critical applications.

In conclusion, Loctite 2701 is a premium solution for demanding applications. Its unique combination of high strength, tolerance for slight oil contamination, exceptional environmental resistance, and the brilliant UV fluorescence feature makes it an invaluable tool for professionals who cannot afford failure. It’s the “green light” for reliability in the most challenging environments.